Buildings are subjected to numerous stresses over their lifespan, including wind and seismic loads, and thermal expansion and contraction. When designing a structure, it's important to consider if the structure and its materials can handle the stresses over the intended life of the building.

This blog post will discuss how to account for wind loading and shear forces that are imposed on a building when using a gypsum panel installed over wood framing.

Mitigating stress in your wood framing

Shear can have several different meanings in the construction industry. For the purpose of this post, we will use “shear” to mean the lateral force that is applied to walls during wind events. A common approach to accommodate shear forces on a building is to sheath the exterior walls with a plywood or oriented strand board (OSB). Plywood and OSB accommodate high shear values over wood framing, however, they are an excellent source for fire propagation. Alternatively, gypsum sheathing is an ideal material to resist fire in the building envelope and to accommodate high shear values over wood framing.

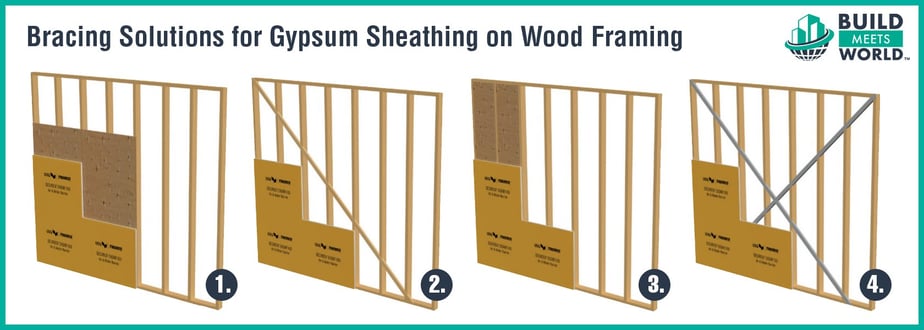

Bracing Methods for Gypsum Sheathing on Wood Framing

The following bracing methods for gypsum sheathing on wood framing are industry recommendations for meeting code requirements for shear values of wall systems. Ultimately, the engineer of record must validate these design configurations for use with a specific project and reference the American Society of Civil Engineers (ASCE) Design Guide 7.

Method 1: Install plywood or OSB sheathing directly to the framing. During installation, the installer covers the wood components with gypsum sheathing. While this method is easy to implement, it can be cost prohibitive as it requires two layers of sheathing on the building exterior.

Method 2: Mount a diagonal piece of wood in a notch created in the framing. The International Residential Code dictates that the bracing shall be placed at an angle between 45 to 60 degrees. This method is economical because it requires only one additional piece of lumber, a circular saw, and chalk line, materials typically found on a job site.

Method 3: The third method can be used in wood framed walls with 2" x 6" studs or greater. A box is constructed of 2" x 4" lumber sheathed with OSB and recessed in the empty stud cavity. The recessed box creates a smooth uninterrupted surface for interior drywall and exterior gypsum sheathing. The engineer must design the inset shear wall panels, specify the amount required, and dictate their placement. When designed correctly, inset shear panels will provide enough lateral load resistance to accommodate all wind and seismic zones.

Method 4: This method utilizes diagonal metal strapping, which can be purchased from a variety of manufacturers. There are three types of metal strapping: Flat, T-profile, and L-profile. All three types can be installed from top plate to sole plate across vertical framing members. In addition, flat strapping can be installed over the top of the framing. T-profile and L-profile strapping must be installed in a diagonal notch in the framing.

When installing gypsum sheathing on wood framing, all four bracing methods help buildings stand the test of time while protecting against structural damage, moisture infiltration, and fire propagation. Work with a design professional to ensure you take the best approach for your particular project.