The permeability of building materials has significant implications on the long-term durability and effectiveness of a structure. So how do air and water permeability differ and how do they impact the performance of specific products?

In this article, we’ll discuss the differences between air and water permeability, their importance on the building envelope, and the ASTM tests used to determine a building material’s level of permeability.

The In's and Outs of Permeability

The typical building is hit relentlessly with water and air from all directions, in all forms and with great fluctuation in temperatures. The term “permeability” generally applies to the ability of a material to allow the passage of air or moisture through it. Construction materials require varying degrees of permeability to enable the structure to remain functional and safe for occupants.

It could be a building owner’s nightmare if the wrong products are selected, with moisture vapor infiltration leading to mold, leaks, occupant complaints and unnecessarily high energy bills.

Product selection isn’t as easy as it sounds, however, as confusion often arises when products are labeled as “permeable,” without specifying whether this relates to water or air.

Air Permeability

Air permeability is critical to the success of a building enclosure because air carries with it a certain amount of moisture, depending upon the degree of ambient humidity. If moisture-laden air enters a building and does not have the opportunity to vacate, structural and/or mold issues can arise.

Air permeability is critical to the success of a building enclosure because air carries with it a certain amount of moisture, depending upon the degree of ambient humidity. If moisture-laden air enters a building and does not have the opportunity to vacate, structural and/or mold issues can arise.

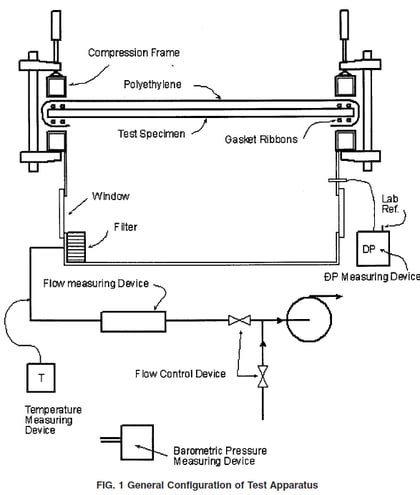

Since the air barrier material is one of the key shields of the wall system, it is looked to most frequently over other building materials for its impermeability to air. The validation of this physical property is conducted through ASTM E2178- Standard Test Method for Air Permeance of Building Materials. In this test (shown to the right), a uniform film of the test material is placed securely over a box, which attempts to pull air through the membrane.1

The method does not apply to the installed air leakage performance of building material, so proper application must ensure that the air barrier system is continuous, with no gaps or breaches. Continuity can be evaluated through ASTM E283- Standard Test Method for Determining Rate of Air Leakage Through Exterior Windows, Skylights, Curtain Walls, and Doors Under Specified Pressure Differences Across the Specimen.

Moisture Vapor Permeability

While all air barrier materials must be impermeable to the flow of air, they can either be permeable or impermeable to moisture vapor depending on numerous factors for the intended design, such as insulation type, location, and more. Due to project intricacies, it is highly recommended to work with a design professional or building science specialist to determine the best course of action for your site conditions.

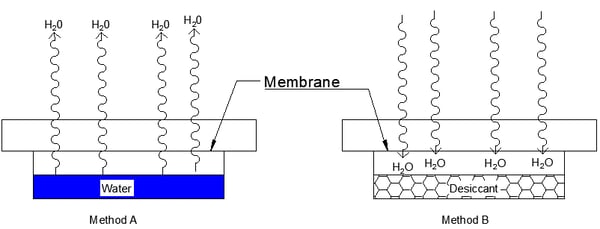

The test widely used to determine the moisture vapor permeability of a building material is ASTM E96- Standard Test Methods for Water Vapor Transmission of Materials. This test looks at the moisture vapor diffusion through the membrane. Two samples (shown below) are prepared by placing the membrane material over two tightly-sealed cups: one that has water (the wet cup) and one with a desiccant or a drying agent (the dry cup). The mass gain or loss of the sample over time is then determined. This measurement is related to diffusion, relative to humidity or moisture moving into or out of the cup.

What does this mean?

Permeability is a key characteristic of building materials that should not be overlooked. The air barrier is an integral part of the greater wall system to provide continuous protection, so it is often evaluated critically for permeability. Because all projects and wall systems are unique, each system should be examined on a case-by-case basis to determine the best product types and combination.

1. ASTM E2178-13, Standard Test Method for Air Permeance of Building Materials, ASTM International, West Conshohocken, PA, 2013, www.astm.org