Exterior Insulation and Finish Systems (EIFS) and EIFS with Moisture Drainage represent an optimum high performance cladding option for their energy-efficiency and design versatility.

As a single sourced solution, EIFS integrate Continuous Insulation (CI), which eliminates thermal bridging, and an air/water-resistive barrier (AWRB) layer, which mitigates air and water infiltration, while providing incidental moisture drainage capacity.

These systems can be easily customized for any architectural style and aesthetic desired. When specifying EIFS, however, there are a number of considerations to address to ensure the design intent, performance expectations and finished appearance are properly conveyed for design, bidding and installation for the best possible execution. Here are the 11 steps architects and specifiers should review when specifying EIFS:

.jpg?width=326&name=Le%20Meridien%20Built%20Over%20Existing%20Buildings%20(1).jpg)

2. Specify for proper impact resistance where impact is anticipated

3. Specify for proper slope and maximum dimensional tolerances for projected horizontal surfaces

4. Engage a 3rd party inspector to review installation quality and consistency

5. Do not mix system components from different EIFS manufacturers

7. Research your warranty options

8. Specify for the ‘exact’ EIFS textured finish desired

9. Investigate EIFS performance enhancements

10. Consider the air/water-resistive barrier

11. Host a pre-installation meeting

1. Select the proper system

In general, EIFS as a polymer-based (PB) insulated cladding assembly is categorized as either barrier or moisture drainage. EIFS with moisture drainage, the more dominant category, offers several performance related options influenced by the height of the building, wall area size, location and environmental or geographical conditions such as a high wind, intensive precipitation or coastline exposure. These systems can be configured for standard, engineered and/or compartmentalized pressure equalized drainage performance.Therefore, the first decision an architect or specifier must evaluate is selecting the appropriate EIFS for the project’s inherent and external influences. From there, the designer should hold the specification through the bidding process and resist the tendency for bidders to push back to a standard drainage performance if the project’s needs dictate otherwise. Consulting with an EIFS manufacturer can be very helpful to determine the best fit for your project.

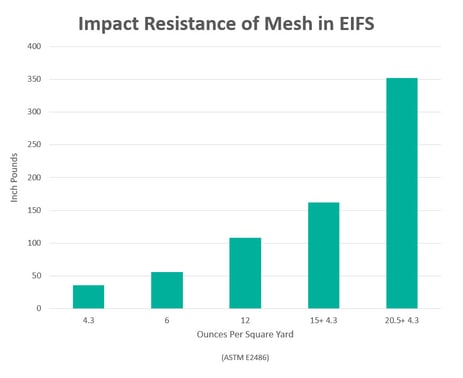

2. Specify for proper impact resistance where impact is anticipated

ASTM E2486, Standard Test Method for Impact Resistance of Class PB and PI Exterior Insulation and Finish Systems (EIFS) establishes 4 impact resistance classifications – Standard, Medium, High and Ultra High – for EIFS which are achieved through increased weights of reinforcing mesh and/or multiple layers of reinforcing mesh. For areas where impact is anticipated, specifying for a High or even Ultra High impact mesh assembly is recommended. The impact resistance classification and associated area(s) of the building must be outlined in the specification and should be supported graphically and/or with notation on elevation drawings.

The EIFS industry recommends High or Ultra High Impact Resistance for all EIFS wall areas within 8’-0” of grade. An Ultra High Impact Mesh Assembly with a layer of standard 4.3 oz / sy reinforcing mesh over a layer of 20 oz. / sy reinforcing mesh will improve impact resistance by 10 times compared to a Standard impact level. In addition, look to select a textured finish that features stone aggregates for enhanced abrasion resistance and even greater protection. Lastly, specify heavy duty “corner mesh” to protect outside corners. If possible, avoid sharp corner angles in high circulation areas where the potential for impact damage can be anticipated.

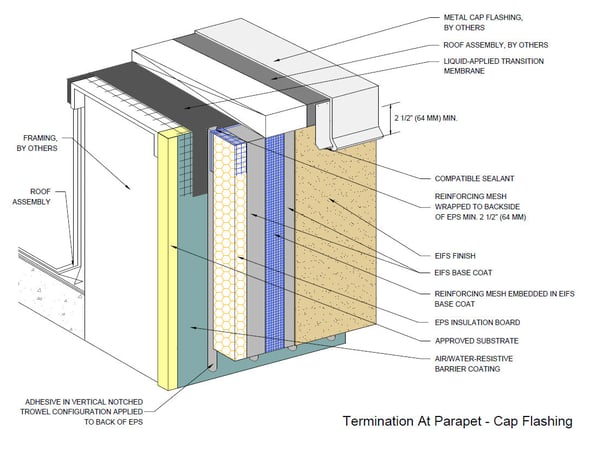

3. Specify for proper slope and maximum dimensional tolerances for projected horizontal surfaces

ASTM C1397, Standard Practice for Application of Class PB Exterior Insulation and Finish Systems (EIFS) and EIFS with Drainage, recommends that all designed projections off the building be sloped rather than horizontally flat. The projection thickness should be no greater than 12 inches and have a minimum 6:12 slope (rise over run). If a projection is greater than 12 inches, it is code defined as a roof plane and must be covered with a metal flashing or appropriate roofing material.

For long-term performance at large projections, it is recommended to specify smoother textured finishes versus coarse or heavy textured finishes to minimize snow and ice retention. Specifying for a Medium or High impact resistance level will enable enhanced protection to hail exposure and applying elastomeric coatings will aid in UV resistance and thermal cycling. Note that EIFS cannot be utilized as a parapet cap regardless of slope or composition.

4. Engage a third party inspector to review installation quality and consistency

Chapter 17 of the International Building Code (IBC) requires for third party inspection of all major layers of application for Barrier EIFS and an inspection for the AWRB) layer in EIFS with Moisture Drainage. Aside from these code inspection requirements, it is highly recommended to work with a third-party building envelope consultant to not only inspect and validate the EIFS cladding installation, but also the other elements of the building envelope such as substrates, flashings, windows, doors, louvers and other alternate claddings, sidings or veneers integration. A third-party consultant can assist in validating the design intent and proper implementation of manufacturer-approved details, connections and transitions, as well as guide coordination of trades, sequencing, required field testing and overall construction.

5. Do not mix system components from different EIFS manufacturers

While EIFS, in general, are similar, each individual EIFS materials are manufactured differently and tested for their long term performance, durability and fire resistance. Allowing for components from different manufacturers introduces materials that are not tested as part of a system, therefore running the risk of incompatibility, system failure, a voided product warranty or worse, a life safety issue.

6. Require that your EIFS are installed by experienced, trained and EIFS manufacturer ‘listed’ applicators

6. Require that your EIFS are installed by experienced, trained and EIFS manufacturer ‘listed’ applicatorsEIFS manufacturers require their contractor customers to receive product, system and installation training prior to in-field applications. Specifying for ‘trained applicator certificate’ in the Submittals Section of your specification is key, but more critical is that you actually receive, review and approve the selected EIFS applicator. With respect to specifying EIFS applicator training requirements, you can additionally require for the applicator and/or applicator firm to be AWCI Certified. The Association of the Wall and Ceiling Industry (AWCI) is the EIFS industry leading source for administering independent third-party professional education for EIFS applicators, and provides updated lists of EIFS-certified contractors for external reference.

7. Research your warranty options

There are many elements to an EIFS warranty that you must research, coordinate and outline in the Warranty Section of your specification. From the term length, coverage of fade and impact resistance, and extension options, there are variables to help you get the most out of your EIFS. Learn more about the specific questions to consider and performance enhancements for EIFS warranties here.

8. Specify for the ‘exact’ EIFS textured finish desired

A major feature of EIFS is its ability to convey any architectural style and represent nearly all desired aesthetic appearances such as stucco, brick, granite, stone, travertine, weathered steel, wood grain and metal panel. Today’s designs tend to incorporate numerous different material aesthetics into one project – all of which can be created as a textured finish option within an EIFS solution. When EIFS is therefore considered, the selected EIFS standard or specialty finish must be properly coded on the elevations, referenced in the exterior finish schedule for the designated area, texture and color; and most importantly, outlined in the Part II, Materials, Finishes Section of the specification. Without this level of synchronization, important application criteria can be missed, leading to poor bidding, improper installation, mistakes or change orders.

9. Investigate EIFS performance enhancements

State-of-the-art acrylic polymer chemistry finds itself well entrenched within the EIFS industry with the development, integration and therefore specification of EIFS textured finish and/or architectural coating performance enhancements. For many years now, Dirt Pick-Up Resistance (DPR) and Proven Mildew Resistance (PMR) have been the industry standard to protect against airborne dirt deposits and/or the growth of mold and algae on EIFS finish or coating surfaces. Today, additional performance enhancements are available with minimal cost impacts that now represent a new opportunity for architects and their EIFS specifications such as:

i. Hydrophobic Water-Repellency – this performance enhancement causes water to bead on the surface of the EIFS textured finish or coating, taking away airborne dirt and helping to keep surfaces cleaner longer and reduce maintenance.

i. Hydrophobic Water-Repellency – this performance enhancement causes water to bead on the surface of the EIFS textured finish or coating, taking away airborne dirt and helping to keep surfaces cleaner longer and reduce maintenance.ii. Lightweight Ergonomic Finish – this performance enhancement, which uses recycled glass as an aggregate component, dramatically reduces the weight of a 5-gallon pail of finish from 70 lbs. to 40 lbs., lowering transportation cost, wear and tear on the applicator contractor and potential job site injury.

iii. Elastomeric Properties – this performance enhancement provides elongation properties within EIFS textured finish and coatings making it ideal for application over those surfaces prone to minor stress cracking such as cement stucco, concrete or CMU, as well as in the restoration / renovation of older stressed EIFS textured finish surfaces.

10. Consider the air/water-resistive barrier

Building codes require the integration of an AWRB behind all claddings. EIFS with Drainage – as a single source cladding – integrates a code-compliant fluid applied AWRB. All other claddings are not single-sourced and do not automatically integrate an AWRB – it must be specified separately. Therefore, the building envelope may have two or more AWRB’s depending on the number and type of claddings, yielding multiple manufacturers, warranties and trades. This complication can lead to challenges with compatibility, transition detailing, sequencing and ultimately performance – short and long-term. As a means of solving this challenge and where EIFS must incorporate their compatible and tested AWRB, consider specifying for the EIFS AWRB to be installed over the entire building and under all claddings, sidings, and veneers. This will create a more single-source focus toward the critical AWRB layer within the overall and complete building envelope.

11. Host a pre-installation meeting

To thoroughly construct and protect any building envelope, it is standard practice to hold a pre-installation conference or meeting on-site and in advance of any AWRB, window/door or cladding installation. A pre-installation meeting is typically called for in the EIFS specification, but it should be additionally referenced in other cladding and envelope component sections as well. A comprehensive pre-installation meeting will include representation from the owner, envelope consultant (see Item 4. above), architect, general contractor, sub-contractors and manufacturers of all exterior building envelope components. The intent of this gathering is to set clear expectations for the sequencing, testing and application of the building materials. For insights on the pre-construction meeting, a separate but equally important meeting, take a look at this blog post.

To thoroughly construct and protect any building envelope, it is standard practice to hold a pre-installation conference or meeting on-site and in advance of any AWRB, window/door or cladding installation. A pre-installation meeting is typically called for in the EIFS specification, but it should be additionally referenced in other cladding and envelope component sections as well. A comprehensive pre-installation meeting will include representation from the owner, envelope consultant (see Item 4. above), architect, general contractor, sub-contractors and manufacturers of all exterior building envelope components. The intent of this gathering is to set clear expectations for the sequencing, testing and application of the building materials. For insights on the pre-construction meeting, a separate but equally important meeting, take a look at this blog post.To get the full benefits of an EIFS-cladding, the architect or specifier should carefully review these 11 items to ensure proper specification for the design and construction of the building façade. A project with these considerations will have greater quality assurance and less risk of building envelope failure.